Transducer Class® Strain Gages: Fueling the Precision Revolution

In the world of precision engineering, your goals demand more than just tools — they demand partners that understand the language of accuracy.

At the heart of every engineering feat lies the need for precise data. Micro-Measurements understands this need intimately. Our Strain Gages (Gauges) are not just components; they are the architects of precision in your projects.

In the hands of engineers and developers, our sensors become the silent heroes, delivering real-world OEM solutions to torque, load, and force sensing challenges. Their practical design is not just about measuring strain; it's about empowering you to achieve your goals seamlessly.

As a leading manufacturer of quality strain gages for OEM solutions, Micro-Measurements has been a steadfast supporter of the sensor industry for many years. We understand that in the pursuit of precision, your goals often extend beyond the ordinary.

That's why we're excited to share how our commitment to excellence is taking a giant leap forward.

NEXT-LEVEL SENSOR SOLUTIONS:

Beyond the Strain Gage Component Level

Given the surge in interest in force, load, and torque sensing solutions, we've expanded our product portfolio to meet this evolving demand.

Micro-Measurements is proud to introduce an array of advanced solutions that go beyond the conventional strain gage component level.

What's NEW in Our Transducer Class® Strain Gages Arsenal:

EXPANDED PRODUCT PORTFOLIO: Our dedication to innovation means offering more than just strain gages. Explore our latest products and services tailored to meet the demands of the sensors industry.

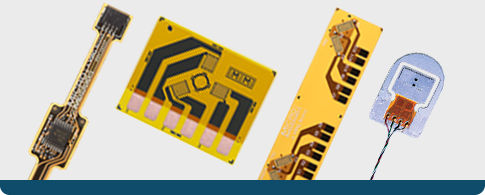

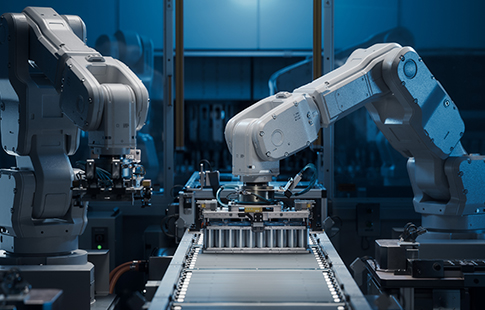

AUTOMATED EXCELLENCE: Scaling up production shouldn't mean compromising precision. Our Strain Gages, with pre-applied self-adhesive or FPC attachment, are meticulously crafted with cutting-edge automated equipment.

MODULE-LEVEL SUPPORT: Overcome the challenges of scaling production with our module-level support. We offer to bond gages to your custom parts, with sourcing seamlessly integrated.

Advanced Sensors Technology to Improve Performance

- Manufactured specifically for high-volume OEM applications using innovative state-of-the-art technology

- Available in a variety of high resistance patterns — Linear, Shear, T-Patterns, and Full-Bridge configurations — with up to 10K ohm resistance values.

- Exceptional gage-to-gage and grid-to-grid matching delivers more uniform gage performance with temperature changes

- Tighter resistance tolerances - down to +/-0.1% even in high resistance gage patterns - facilitate simpler balance of the Wheatstone bridge circuitry

- Gold-plated solder tabs (on Karma foil patterns) and Epoxy Encapsulation ensure active grid protection

CUSTOM GAGE & SENSOR DESIGN FOR OEM APPLICATIONS

Get tailored strain gages and hybrid sensors for unique specifications, including custom pattern geometries and materials. Experience consistent performance with our hybrid flex sensors, perfect for automotive, medical, and industrial applications.

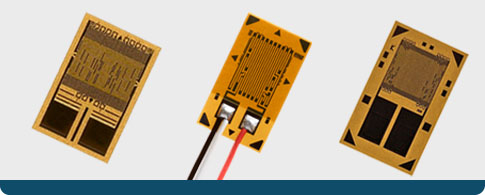

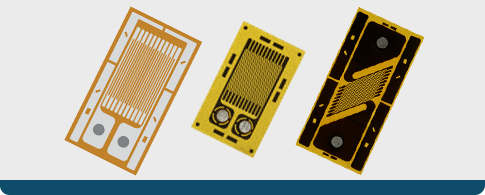

LINEAR PATTERNS

Linear pattern gages are typically used in S-Beam, binocular, Reverse Bending and Dual Beam load cell and pressure transducer designs. They are available in single linear or dual linear configurations and customizable grid sizes to allow for gaging one side or both sides of the spring element.

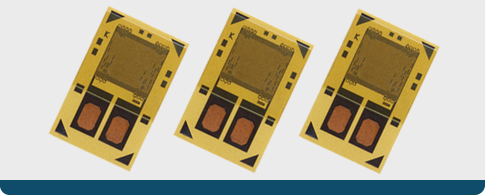

0° - 90° PATTERNS

Bi-axial strain gages are designed for use in column load cells (to cancel bending strain) or simple cantilever applications (for gaging a single side of the spring element).

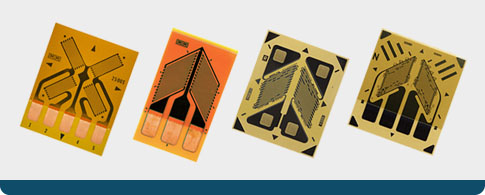

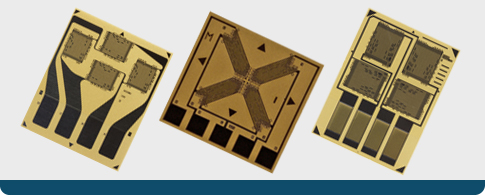

SHEAR/TORQUE ROSETTES

Micro-Measurements Shear/Torque Rosette Transducer Gages are designed for measuring shear strain and torque, available in individual and multiple grid patterns, and come in lengths from 0.062” (1.57 mm) to 0.250” (6.35 mm).

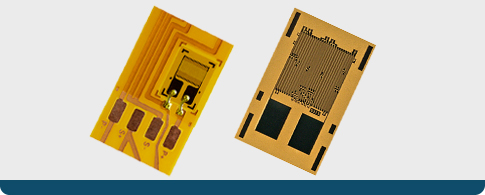

HIGH RESISTANCE PATTERNS

High resistance pattern gages are a preferred choice for low power consumption in various applications. These include electronic torque wrenches; pocket (jewelry) scales; bicycle and motorcycle sensing and testing equipment; and applications such as wireless telemetry on rotating components.

Linear, shear, bi-axial and diaphragm (circular and linear pattern) gages, arranged as individual, half-bridge and full-bridge configurations are available in resistance values from 350 Ω to 20 kΩ.

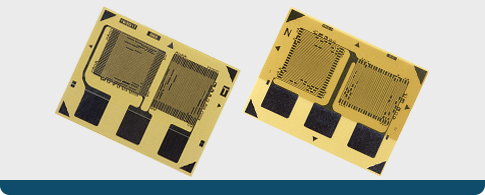

FULL-BRIDGE PATTERNS

Full-Bridge gages are a preferred choice for aerospace, medical, automotive, and subsea applications. Full-Bridge designs provide simplified, precise alignment and reduced bonding operations.

DIAPHRAGM PATTERNS

Diaphragm pattern gages are available as square-trimmed diaphragm gages (standard) or circular-trimmed diaphragm gages (optional). Different trim diameters, depending on the diaphragm size, are available. Several standard circular trim sizes are available to fit a wide range of diaphragm diameters.

PLATINUM-TUNGSTEN ALLOY STRAIN GAGES

This unique, high gage factor strain gage series offers increased strain sensitivity (4+ gage factor) – more than double all other foil strain gage types.

BONDABLE RESISTORS FOR TRANSDUCER COMPENSATION

Our unique, bondable resistors deliver tighter tolerance, better stability, and shorter lead times. These innovative resistors ensure repeatable test data, when compared to previous-generation conventional resistor types.

TECHNICAL DATABOOKS

See our technical databooks that support our advanced measurement technology.

RESOURCES

Learn about our stress analysis products, watch informative videos, and explore our large knowledge base.

STRAINBLOG

Questions and answers on the go! Listen to Micro-Measurements experts explain the many facets of strain gage technology.

TRAINING

Benefit from an extensive series of regularly scheduled, hands-on technical workshops and short courses.