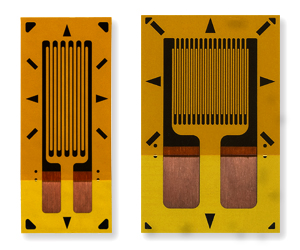

Strain Gage Linear Patterns (Uniaxial Stress)

The gage pattern refers cumulatively to the shape of the grid, the number and orientation of the grids in a multiple-grid gage, the solder tab configuration, and various construction features that are standard for a particular pattern.

The linear pattern strain gages measures strain in a single direction. Linear Pattern strain gauge sensors are used for both general use applications: Fatigue Testing, Concrete Testing, Crack Propagation, Dog Bone testing.

CEA Series Linear Strain Gages |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

|

Configuration

|

Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC |

Temperature Range |

Options | ||||||||

| Linear Strain Gage | 015UWA | 120 | 0.015 [0.38] | 0.02 [0.51] | 0.24 [6.1] | 0.18 [4.6] |

00, 03, 05, 06, 09, 13 |

–100° to +350°F (–75° to +175°C) |

P2, SP11 | ||||||||

| 032UWA | 120 , 350 | 0.032 [0.81] | 0.06 [1.52] | 0.27 [6.9] | 0.19 [4.8] | ||||||||||||

| 062UWA | 120 , 350 , 1000 | 0.062 [1.57] | 0.12 [3.05] | 0.31 [7.9] | 0.19 [4.8] | ||||||||||||

| 125UNA | 120 , 350 | 0.125 [3.18] | 0.1 [2.54] | 0.38 [9.7] | 0.19 [4.8] | ||||||||||||

| 125UWA | 120 , 350 | 0.125 [3.18] | 0.18 [4.57] | 0.42 [10.7] | 0.27 [6.9] | ||||||||||||

| 250UNA | 120 , 350 , 1000 | 0.25 [6.35] | 0.12 [3.05] | 0.52 [13.2] | 0.22 [5.6] | ||||||||||||

| 250UWA | 120 , 350 | 0.25 [6.35] | 0.18 [4.57] | 0.55 [14.0] | 0.27 [6.9] | ||||||||||||

| 375UWA | 120 , 350 | 0.375 [9.53] | 0.18 [4.57] | 0.67 [17.0] | 0.27 [6.9] | ||||||||||||

| 500UWA | 120 , 350 | 0.5 [12.70] | 0.18 [4.57] | 0.8 [20.3] | 0.27 [6.9] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Linear Strain Gage - Tabs on one side | 062UBA | 350 | 0.062 [1.57] | 0.12 [3.05] | 0.21 [5.3] | 0.34 [8.6] | |||||||||||

| 125UBA | 350 | 0.125 [3.18] | 0.16 [4.06] | 0.34 [8.6] | 0.39 [9.9] | ||||||||||||

| 250UBA | 350 | 0.25 [6.35] | 0.16 [4.06] | 0.42 [10.7] | 0.42 [10.7] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

| M-Bond 600 Kit | Two-component, solvent-thinned, epoxy-phenolic strain gage adhesive for high-performance | –452° to +500°F (–268° to +260°C) | |||||||||||||||

C4A Series Linear Strain Gages |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

| Configuration | Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC | Temperature Range | Options | ||||||||

| Gages With Pre-attached Cables | 060SL | 120 , 350 | 0.06 [1.52] | 0.1 [2.54] | 0.24 [6.0] | 0.19 [4.9] |

06, 09, 13 |

–60° to +180°F (–50° to +80°C) |

23P, 39P |

||||||||

| 125SL | 120 , 350 | 0.125 [3.20] | 0.1 [2.54] | 0.28 [7.1] | 0.19 [4.9] | ||||||||||||

| 235SL | 120 , 350 | 0.235 [5.97] | 0.1 [2.54] | 0.37 [9.4] | 0.19 [4.9] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

|

Two-component, 100%-solids epoxy system for general purpose strain gages, Highly resistant to moisture and most chemicals, Cryogenic applications require very thin gluelines |

–320° to +200°F (–195° to +95°C) | ||||||||||||||||

C5K Series Linear Strain Gages |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

| Configuration | Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC | Temperature Range | Options | ||||||||

| Gages With Pre-attached Cables | S5145 | 350 | 0.030 [0.76] | 0.063 [1.60] | 0.12 [3.1] | 0.10 [2.6] |

03, 05, 06, 09, 13 |

–100° to +400°F (–75° to +205°C) |

23P, 39P, 2R |

||||||||

| NEW! | 050LK | 5000 | 0.050 [1.27] | 0.073 [1.85] | 0.17 [4.4] | 0.14 [3.6] | |||||||||||

| NEW! | 125LK | 350, 5000 | 0.125 [3.20] | 0.065 [1.65] | 0.25 [6.3] | 0.14 [3.6] | |||||||||||

| 400LK | 5000 | 0.394 [10.00] | 0.102 [2.59] | 0.55 [14.0] | 0.16 [4.0] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

| M-Bond 600 Kit | Two-component, solvent-thinned, epoxy-phenolic strain gage adhesive for high-performance | –452° to +500°F (–268° to +260°C) | |||||||||||||||

WK Series Linear Strain Gages |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

| Configuration | Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC | Temperature Range | Options | ||||||||

| Linear Strain Gage | 031CF | 120 , 350 | 0.031 [0.79] | 0.062 [1.57] | 0.19 [4.8] | 0.14 [3.6] |

00, 03, 05, 06, 09, 13 |

–452° to +550°F (–269° to +290°C) |

W, SP11 |

||||||||

| 031DE | 350 | 0.031 [0.79] | 0.032 [0.81] | 0.27 [6.9] | 0.12 [3.0] | ||||||||||||

| 060CD | 1000 | 0.06 [1.52] | 0.1 [2.54] | 0.28 [7.1] | 0.2 [5.1] | ||||||||||||

| 062AP | 350 | 0.062 [1.57] | 0.062 [1.57] | 0.26 [6.6] | 0.16 [4.1] | ||||||||||||

| 062AQ | 5000 | 0.062 [1.57] | 0.062 [1.57] | 0.26 [6.6] | 0.15 [3.8] | ||||||||||||

| 125AC | 1000 | 0.125 [3.18] | 0.125 [3.18] | 0.4 [10.2] | 0.22 [5.6] | ||||||||||||

| 125AD | 350 | 0.125 [3.18] | 0.125 [3.18] | 0.4 [10.2] | 0.22 [5.6] | ||||||||||||

| 125BB | 350 | 0.125 [3.18] | 0.088 [2.24] | 0.43 [10.9] | 0.22 [5.6] | ||||||||||||

| 125BT | 350 | 0.125 [3.18] | 0.062 [1.57] | 0.37 [9.4] | 0.16 [4.1] | ||||||||||||

| 125BZ | 1000 | 0.125 [3.18] | 0.062 [1.57] | 0.29 [7.4] | 0.13 [3.3] | ||||||||||||

| 250AE | 1000 | 0.25 [6.35] | 0.25 [6.35] | 0.57 [14.5] | 0.36 [9.1] | ||||||||||||

| 250AF | 350 | 0.25 [6.35] | 0.25 [6.35] | 0.57 [14.5] | 0.36 [9.1] | ||||||||||||

| 250BF | 1000 | 0.25 [6.35] | 0.125 [3.18] | 0.52 [13.2] | 0.22 [5.6] | ||||||||||||

| 250BG | 350 | 0.25 [6.35] | 0.125 [3.18] | 0.52 [13.2] | 0.22 [5.6] | ||||||||||||

| 250BK | 1000 , 3000 | 0.25 [6.35] | 0.175 [4.45] | 0.58 [14.7] | 0.27 [7.4] | ||||||||||||

| 375BG | 350 | 0.375 [9.53] | 0.187 [4.75] | 0.71 [18] | 0.29 [7.6] | ||||||||||||

| 500BH | 350 | 0.5 [12.70] | 0.175 [4.45] | 0.92 [23.4] | 0.3 [3.8] | ||||||||||||

| 500GB | 350 | 0.5 [12.70] | 0.06 [1.52] | 0.75 [19.1] | 15.00% | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Linear Strain Gage - Tabs on both sides of the grid | 031EC | 350 | 0.031 [0.79] | 0.032 [0.81] | 0.17 [4.3] | 0.23 [5.8] | |||||||||||

| 062ED | 350 | 0.062 [1.57] | 0.062 [1.57] | 0.21 [5.3] | 0.29 [7.4] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Linear Strain Gage - Tabs on one side | 032SG | 1200 | 0.032 [0.81] | 0.032 [0.81] | 0.16 [4.1] | 0.19 [4.8] | |||||||||||

| 050SB | 350 | 0.05 [1.27] | 0.04 [1.02] | 0.19 [4.8] | 0.19 [4.8] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

| M-Bond 600 Kit | Two-component, solvent-thinned, epoxy-phenolic strain gage adhesive for high-performance | –452° to +500°F (–268° to +260°C) | |||||||||||||||

EA Series Linear Strain Gages |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

| Configuration | Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC | Temperature Range | Options | ||||||||

| Linear Strain Gage | 015DJA | 120 | 0.015 0.38] | 0.02 [0.51] | 0.23 [5.8] | 0.12 [3.0] | 00, 03, 05, 06, 09, 13 | –100° to +350°F (–75° to +175°C) | E, EL, P, W, SP11 | ||||||||

| 015LA | 120 | 0.015 0.38] | 0.02 [0.51] | 0.18 [0.46] | 0.1 [2.5] | ||||||||||||

| 031CEA | 350 | 0.031 [0.79] | 0.062 [1.57] | 0.23 [5.8] | 0.16 [4.1] | ||||||||||||

| 031CF | 120 | 0.031 [0.79] | 0.062 [1.57] | 0.19 [4.8] | 0.14 [3.6] | ||||||||||||

| 031DE | 120 , 350 | 0.031 [0.79] | 0.032 [0.81] | 0.27 [6.9] | 0.12 [0.12] | ||||||||||||

| 031GEA | 350 | 0.031 [0.79] | 0.062 [1.57] | 0.12 [3.1] | 0.1 [2.5] | ||||||||||||

| 045AL | 350 | 0.045 [1.14] | 0.045 [1.14] | 0.22 [5.6] | 0.14 [3.6] | ||||||||||||

| 050AH | 120 | 0.05 [1.27] | 0.04 [1.02] | 0.23 [5.8] | 0.14 [3.6] | ||||||||||||

| 060CD | 350 | 0.06 [1.52] | 0.1 [2.54] | 0.28 [7.1] | 0.2 [5.1] | ||||||||||||

| 062AK | 120 | 0.06 [1.52] | 0.062 [1.57] | 0.27 [6.9] | 0.14 [3.6] | ||||||||||||

| 062AP | 120 | 0.062 [1.57] | 0.062 [1.57] | 0.26 [6.6] | 0.16 [4.1] | ||||||||||||

| 062AQA | 350 | 0.062 [1.57] | 0.062 [1.57] | 0.26 [6.6] | 0.15 [5.8] | ||||||||||||

| 062DN | 350 | 0.062 [1.57] | 0.062 [1.57] | 0.34 [8.6] | 0.18 [4.6] | ||||||||||||

| 070LC | 350 | 0.07 [1.78 | 0.022 [0.56] | 0.24 [6.1] | 0.09 [2.3] | ||||||||||||

| 125AC | 350 | 0.125 [3.18] | 0.125 [3.18] | 0.4 [10.2] | 0.22 [5.6] | ||||||||||||

| 125AD | 120 | 0.125 [3.18] | 0.125 [3.18] | 0.4 [10.2] | 0.22 [5.6] | ||||||||||||

| 125BT | 120 | 0.125 [3.18] | 0.062 [1.57] | 0.37 [9.4] | 0.16 [4.1] | ||||||||||||

| 125BZA | 350 | 0.125 [3.18] | 0.062 [1.57] | 0.29 [7.4] | 0.13 [3.3] | ||||||||||||

| 250AE | 350 | 0.25 [6.35] | 0.25 [6.35] | 0.57 [14.5] | 0.36 [9.1] | ||||||||||||

| 250BF | 350 | 0.25 [6.35] | 0.125 [3.18] | 0.52 [13.2] | 0.22 [5.6] | ||||||||||||

| 250BG | 120 | 0.25 [6.35] | 0.125 [3.18] | 0.52 [13.2] | 0.22 [5.6] | ||||||||||||

| 250BK | 1000 | 0.25 [6.35] | 0.175 [4.45] | 0.58 14.7] | 0.27 [6.9] | ||||||||||||

| 500BH | 120 | 0.5 [12.70] | 0.175 [4.45] | 0.92 [23.4] | 0.3 [7.6] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Linear Strain Gage - Tabs on both sides of the grid | 015EH | 120 | 0.015 [0.38] | 0.02 [0.51] | 0.15 [3.8] | 0.19 [4.8] | |||||||||||

| 031EC | 120 | 0.031 [0.79] | 0.032 [0.81] | 0.17 [4.3] | 0.23 [5.8] | ||||||||||||

| 062EN | 350 | 0.062 [1.57] | 0.062 [1.57] | 0.23 [5.8] | 0.31 [7.9] | ||||||||||||

| 125ARA | 350 | 0.125 [3.18] | 0.102 [2.59] | 0.22 [5.5] | 0.37 [9.4] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Linear Strain Gage - Tabs on one side | 032SG | 120 | 0.032 [0.81] | 0.032 [0.81] | 0.16 [4.1] | 0.19 [4.8] | |||||||||||

| 050SB | 120 | 0.05 [1.27] | 0.04 [1.02] | 0.19 [4.8] | 0.19 [4.8] | ||||||||||||

| 125EP | 350 | 0.125 [3.18] | 0.125 [3.18] | 0.28 [7.1] | 0.35 [8.9] | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

| M-Bond 600 Kit | Two-component, solvent-thinned, epoxy-phenolic strain gage adhesive for high-performance | –452° to +500°F (–268° to +260°C) | |||||||||||||||

Advanced Sensors Technology is developing the tools of the future!

Micro-Measurements Announces Successful Integration of Advanced Sensors Technology into linear pattern strain gage sensors for Industry best-in-class design and performance characteristics. Advanced Sensors Technology applies tangible specification and manufacturing process improvements, along with industry-exclusive strain gage sensor design techniques, for direct customer benefit. The innovation behind Advanced Sensors Technology reflects many decades of Micro-Measurements R&D experience, gained across a global portfolio of thousands of successful applications, with other refinements achieved via ongoing customer feedback.

Stress Analysis Linear Pattern Strain Gages features:

- Gage patterns designed for measuring strain in a single direction

- Resistance value

- Single-grid and parallel dual-grid patterns

- Gage lengths from 0.0008" (0.20 mm) to 4.000" (101.6 mm)

- Self-Temperature Compensation (S-T-C)

- Operating temperature ranges from –452° to +750°F [–269° to +400°C]

VIDEOS

Explore our extensive collection of tutorials and informational videos on a variety of strain measurement topics.

STRAINTALKS

Explore our free education seminars aimed at helping Design and Test Engineers understand strain gage theory selection, preparation, performance, installation, configuration, and more.

STRAINBLOG

Questions and answers on the go! Listen to Micro-Measurements experts explain the many facets of strain gage technology.

TRAINING

Benefit from an extensive series of regularly scheduled, hands-on technical workshops and short courses.