Monitor Structural Health, Machine Health, and Human Health

Structural Health Monitoring (SHM) systems provide accurate and virtually real-time information on the performance and condition of any infrastructure. SHM systems increase safety and simultaneously reduce uncertainty and excessive operating expenses. Structural Health Monitoring systems—built with Micro-Measurements’ high-quality, easy to install, bondable and weldable foil strain gages— are used for remote monitoring of critical structures, including bridges, buildings, dams, tunnels, wind turbines, industrial facilities and light poles.

Keep Your Eye on the “Ball”

SHM systems provide accurate and near-real-time information about the performance and condition of structures. Collecting precise and accurate strain data helps you identify potential problems with any structure at an early stage—even from a remote location. With these products, it’s never been easier to keep your eye on the ball.

While SHM will never replace visual inspection and human judgment, it can be used to keep a “remote eye” on critical structures.

Some key benefits of SHM:

- Minimizes inspection cycles

- Alerts engineers to any changes

- Supports planning and designing maintenance activities

- Increases safety

- Reduces uncertainty

- Mitigates operating expenses

To learn more about Micro-Measurements’ strain gages for Structural Health Systems, get in touch with an expert.

INFRASTRUCTURE/CONSTRUCTION/CIVIL ENGINEERING

Micro-Measurements’ foil strain gages are the most robust solution to monitor strain in concrete and metal structures. Our gages are installed on structural components in bridges and buildings to measure stress and compare these measurements to analytical models and stress calculations.

POWER GENERATOR/TURBINE MANUFACTURES

Micro-Measurements’ strain gages help detect equipment failure, malfunction and unusual conditions found during regular operation or maintenance activities. Our sensing systems—including wireless and telemetry capabilities—accurately measure variables in pumps and other equipment that experience high thrust loads.

SHIP BUILDERS

Micro-Measurements’ strain gages are used to measure the torque in ship parts such as fans, generators, wheels, or propellers in a motor, turbine, or engine. Our strain gages are also used to measure and monitor mooring forces of ships. Common approaches include mounting a tension strain gage load cells in line with mooring ropes or using a shear pin force strain gage transducer.

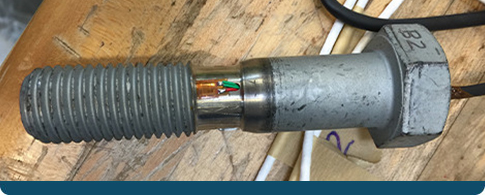

FASTENER TESTING

Fasteners are ubiquitous in a variety of everyday structures, including infrastructure, equipment, and vehicles. These structures need to be safe and reliable. That’s why fasteners must perform to expectations and hold up to wear and tear such as stress, vibration, unexpected loads, and environmental conditions. Micro-Measurements’ metal foil strain gages are key components in any fastener testing. These tests help to identify potential problems at an early stage, extend service life, and help reduce operating and replacement costs.

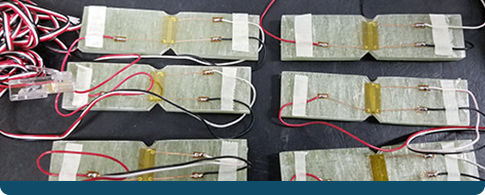

RESIDUAL STRESSES

An inevitable, and potentially costly, effect of the manufacturing and fabricating processes is residual stress. Most commonly, residual stresses are detrimental— contributing to fatigue and other structural failures that often go unrecognized until after a malfunction or failure occurs. The hole-drilling strain gage method is a relatively simple procedure and has been standardized in ASTM Standard Test Method E 837. Learn more about the general theory of residual stress measurements in Micro-Measurements Tech Note TN-503, “Measurement of Residual Stresses by the Hole-Drilling Strain Gage Method”.

GEOTECHNICAL/GEOSCIENCE

Micro-Measurements’ strain gages are expertly designed to meet unique challenges such as those found in constructions occurring on the earth’s surface or subsurface. Our gages help determine mechanical properties for structures such as earth-filled dams, retaining walls, embankments, tunnels, dikes and levees, channels, reservoirs and landfills.

BRIDGES

Micro-Measurements’ foil strain gages are used in bridge structures around the world to measure strain, displacement, force, temperature, inclination, bending movements and alignment. A permanent installation provides long-term monitoring of the structure’s health, while a temporary installation ensures safe working conditions during a repair.

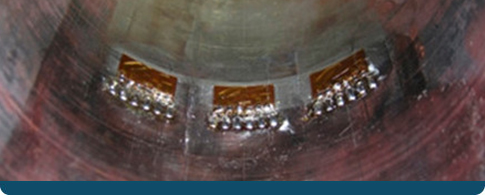

PIPELINES

Micro-Measurements’ metal foil strain gages can be attached to various points along oil and gas pipelines to offer continuous, remote monitoring of the structures and help prevent threats to the flow inside the pipe as well as potential threats to the environment.

RAIL MONITORING

Micro-Measurements offers a wide range of strain gages that provide long-term structural monitoring solutions for railways. The strain on rails, such as axial tension or compression, can and should be measured and monitored. Warnings enable maintenance, minimize impact on rail traffic, and ensure safety.

DAMS

Micro-Measurements’ impressive collection of strain gages are well suited for monitoring and analyzing the behavior of a dam’s structural element. When strain gages are used during the planning, design, construction and operation of the dam, the performance of the dam’s structure is reliable and safe. In addition, our strain gages are suitable to ascertain data related to other parts of the dam, such as the reservoir and river basin, to help ensure normal operation and safety.

MATERIAL & ENDURANCE TESTING

Precision, speed and reliability are critical features in any force mechanism systems found in the metals processing industry. Metal foil gages are used to determine how long an application can meet processing load demands. Measurements types include linear and shear force, torque, pressure, tension and compression.

SPORT, LEISURE, & TRAINING EQUIPMENT

Micro-Measurements designs and manufactures hybrid sensors and strain gages, used in exercise and sports therapy equipment to monitor and/or control the level of effort exerted by the patient, or to measure and track an athlete’s performance.