Special Use Instruments

For many measurement applications additional equipment may be required, for example, quality control of a strain gage installation, applications in harsh environments, or other measurement requirements. Micro-Measurements manufactures and supplies many special use Instruments and supporting products to provide a complete solution for your precision measurement needs.

The Model 700B Portable Welder

The Model 700B is an update to our Model 700 welding and soldering unit which has been used for decades for installing many thousands of strain gages worldwide. It offers a modern, compact design with a removable Lithium-ion battery and has a rugged exterior for use in adverse field conditions.

For more information:

The Model 700 Portable Welder

The Model 700 is used to install strain gages in harsh environment where the stringent surface preparation processes and adhesive cure schedule are difficult or impossible to achieve. Special strain gages are manufactured by bonding a conventional foil gage to a thin shim which can then be spot-welded to a structure. With a rechargeable battery, it can be used to install gages outside in cold, dirty or wet environments with ease. Additionally, our high temperature weldable gages enable fast installations on exhausts and manifolds for temperatures approaching 1000°C (1800°F).

For more information:

The Model 700 Portable Welder Product Page

The Model 700 Welder Datasheet

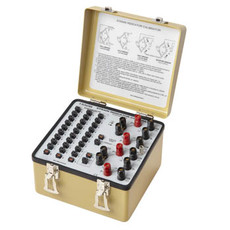

The V/E-40 Strain Gage Simulator

An accurate, stable, compact, ive-decade resistor specially designed to simulate the behaviour of strain gages and RTDs, and for use in a broad range of measurement and calibration applications. As a precision strain gage simulator, the V/E-40 can be used to measure nonlinearity of the instrumentation in quarter bridge operation, or to verify instrument calibration over the anticipated measurement range. It is also well suited to measuring desensitization of the strain gage circuit due to the finite resistance of the strain gage leadwire system.

For more information:

V/E-40 Strain Gage Simulator product page

The Model 1300 Gage Installation Tester

The Micro-Measurements Model 1300 Gage Installation Tester enables quick and simple qualitative measurements that indicate the quality of the installation. Potential damage or degradation can be quickly identified with just three tests - resistance (Ω), deviation (5% and 1%), and insulation (MΩ).

For more information:

Model 1300 Installation Tester product page

Model 1300 Installation datasheet

The 1550B Calibrator

Sound engineering and laboratory practices require that the instrumentation used to make critical strain measurements be periodically calibrated to verify that it is within the manufacturer’s original specifications. Additionally, each type of strain indicator exhibits some degree of nonlinearity, especially for large strains during quarter-bridge operation. Since this is the most common stress analysis application of strain gages, it is important that the strain indicator be calibrated in this mode. Instrumentation span should also be checked at a number of points before each important test to avoid inaccurate data.

For more information:

The 1550B Calibrator product page

The 1550B Calibrator Datasheet

RS-200 Milling Guide

Our RS-200 facilitates measurements of residual stresses which are present in many structures. The high speed drilling equipment is designed to enable precision drilling of a small hole using a dental turbine to minimise any detrimental effect on the measurement. In combination with a suitable strain gage and measuring instrument such as our P3, getting consistent strain values for analysis is made simple. The process follows ASTM E837.Our RS-200 facilitates measurements of residual stresses which are present in many structures. The high speed drilling equipment is designed to enable precision drilling of a small hole using a dental turbine to minimise any detrimental effect on the measurement. In combination with a suitable strain gage and measuring instrument such as our P3, getting consistent strain values for analysis is made simple. The process follows ASTM E837.

For more information:

RS-200 Milling Guide Datasheet

VIDEOS

Explore our extensive collection of tutorials and informational videos on a variety of strain measurement topics.

Pacific

Pacific Instruments is an industry leader in the design, manufacture and support of state-of-the-art, computer-automated physical measurement systems.

STRAINBLOG

Questions and answers on the go! Listen to Micro-Measurements experts explain the many facets of strain gage technology.

RESOURCES

Learn about our stress analysis products, watch informative videos, and explore our large knowledge base.