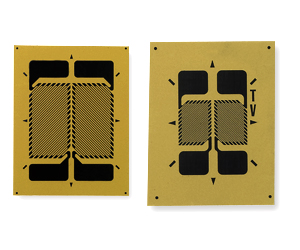

Strain Gage Shear Patterns

The gage pattern refers cumulatively to the shape of the grid, the number and orientation of the grids in a multiple-grid gage, the solder tab configuration, and various construction features that are standard for a particular pattern. Torque measurement is a very common application, used to measure engine power output on propshafts and driveshafts, driver input through steering wheels, tightening bolts, or anywhere a component is subjected to a twisting force.

When the shaft is loaded in torsion, it creates a state of pure shear and the applied torque can be found by orienting rosettes where the gridlines are positioned at 45 degrees to the axis of the shaft. Some common applications can be found in pulp and paper mills for measuring efficiency, output shafts for large ships for optimum engine setup, and even power monitoring for cyclists so they can determine how much energy was expended during training, and, of course, there are many others. For most of these applications, the strain gages are used to construct a full Wheatstone bridge circuit to double the sensitivity to torque and cancel unwanted effects due to axial or bending load components.

CEA Series Shear Strain Gages |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

|

Configuration

|

Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC |

Temperature Range |

Options | ||||||||

| Tee Rosette Strain Gage | 062UVA | 350 |

0.062 [1.57] |

0.063 [1.60] |

0.42 [10.7] |

0.23 [5.8] |

00, 03, 05, 06, 09, 13 |

–100° to +350°F (–75° to +175°C) |

P2, SP11 |

||||||||

| 187UVA | 350 |

0.187 [4.75] |

0.150 [3.81] |

0.63 [16.0] |

0.39 [9.9] |

||||||||||||

| 125USA | 120, 350, 1000 |

0.125 [3.18] |

0.350 [1.52] |

0.48 [12.19] |

0.40 [10.16] |

||||||||||||

| 250USA | 120, 350, 1000 |

0.250 [6.35] |

0.120 [3.05] |

0.96 [24.4] |

0.80 [20.3] |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

| M-Bond 600 Kit | Two-component, solvent-thinned, epoxy-phenolic strain gage adhesive for high-performance | –452° to +500°F (–268° to +260°C) | |||||||||||||||

EA Series Shear Strain Gages |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

| Configuration | Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC | Temperature Range | Options | ||||||||

| Shear Strain Gage Patterns | 062TH | 120 |

0.062 [1.57] |

0.055 [1.40] |

0.27 [6.9] |

0.21 [5.3] |

00, 03, 05, 06, 09, 13 |

–100° to +350°F (–75° to +175°C) |

E, EL, P, W, SP11 |

||||||||

| 062TVA | 350 |

0.062 [1.57] |

0.055 [1.40] |

0.27 [6.9] |

0.21 [5.3] |

||||||||||||

| 062TW | 120 , 350 |

0.062 [1.57] |

0.055 [1.40] |

0.27 [6.9] |

0.21 [5.3] |

||||||||||||

| 125TK | 350 |

0.125 [3.18] |

0.110 [2.79] |

0.40 [10.2] |

0.31 [7.9] |

||||||||||||

| 125TR | 350 |

0.125 [3.18] |

0.125 [3.18] |

0.36 [9.1] |

0.47 [11.9] |

||||||||||||

| 250TK | 350 |

0.25 [6.35] |

0.22 [5.59] |

0.74 [18.8] |

0.55 [14.0] |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

|

Two-component, solvent-thinned, epoxy-phenolic strain gage adhesive for high-performance |

–452° to +500°F (–268° to +260°C) | ||||||||||||||||

WK Series Shear Strain Gages |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

| Configuration | Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC | Temperature Range | Options | ||||||||

| Tee Rosette Strain Gage | 125TK | 1000 |

0.125 [3.18] |

0.110 [2.79] |

0.40 [10.2] |

0.31 [7.9] |

00,03,05, 06,09,13 |

–452° to +550°F (–269° to +290°C) |

W, SP11 |

||||||||

| 125TR | 350, 1000 |

0.125 [3.18] |

0.125 [3.18] |

0.36 [9.1] |

0.47 [11.9] |

||||||||||||

| 250TK | 350, 1000 |

0.250 [6.35] |

0.220 [5.59] |

0.74 [18.8] |

0.55 [14.0] |

||||||||||||

| 250TR | 1000 |

0.250 [6.35] |

0.250 [6.35] |

0.70 [17.8] |

0.96 [24.4] |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

| M-Bond 600 Kit | Two-component, solvent-thinned, epoxy-phenolic strain gage adhesive for high-performance | –452° to +500°F (–268° to +260°C) | |||||||||||||||

C2A Series Shear Strain Gages |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| [in/mm] | [in/mm] | [in/mm] | [in/mm] | ||||||||||||||

| Configuration | Pattern | Res. [Ω] |

Gage Length |

Gage Width |

Matrix Length |

Matrix Width |

Standard STC | Temperature Range | Options | ||||||||

| Gages With Pre-attached Cables | 062LV | 120 , 350 |

0.062 [1.57] |

0.050 [1.27] |

0.26 [6.6] |

0.27 [6.9] |

06, 09, 13 |

–60° to +180°F (–50° to +80°C) |

W, SP11 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

| Temperature Range | |||||||||||||||||

| Typically used with: | M-Bond 200 Kit | Room temperature instant curing strain gage adhesive | –25° to +150°F (–30° to + 65°C) | ||||||||||||||

| M-Bond AE-10 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +400°F (–195° to +204°C) | |||||||||||||||

| M-Bond AE-15 Kit | Two-component, 100%-solids epoxy system for general purpose strain gages Room temperature cure, highly resistant to moisture and most chemicals |

–320° to +200°F (–195° to +95°C) | |||||||||||||||

Advanced Sensors Technology Shear and Torque Strain Gages

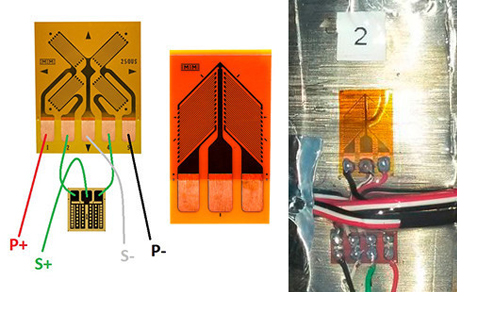

Torque loads cause shear strain in the structure to which the torsional loads are being applied. This is a good thing, because strain gages can measure these shear strains. That's actually not a precisely true statement. Bonded electrical resistance strain gages do not respond to pure shear strains. Fortunately, associated with all shear strains are two normal components of strain, tension and compresion, which strain gages easily sense. This is why it takes two strain gage sensing grids to resolve one shear strain value. For mathematical convenience, these grids are normallyoriented at ±45° to the measurement direction (90° between the two grids), allowing the gage, when properly connected to a strain indicator instrument, to directly display strain magnitude. But, the grids could be oriented at any relative to one another and the shear strain casn be calculated.

Torque transducers provide a convenient way of measuring torque-loads being applied to a structure, shaft, bolt, door knob, and so on. The sensor used in many high quality torque transducers is a Micro-Measurements Transducer Class shear-strain gage. These precision measuring devices allow designers to optimize structures for anticipated loads.

VIDEOS

Explore our extensive collection of tutorials and informational videos on a variety of strain measurement topics.

STRAINTALKS

Explore our free education seminars aimed at helping Design and Test Engineers understand strain gage theory selection, preparation, performance, installation, configuration, and more.

STRAINBLOG

Questions and answers on the go! Listen to Micro-Measurements experts explain the many facets of strain gage technology.

TRAINING

Benefit from an extensive series of regularly scheduled, hands-on technical workshops and short courses.