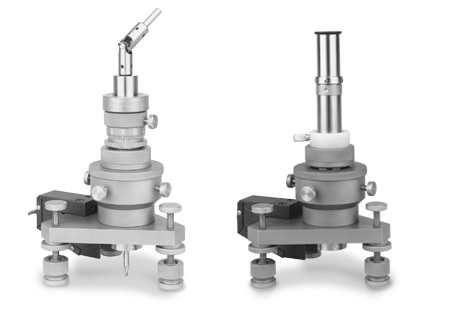

RS-200 Residual Stress Milling Guide

The most widely used practical technique for measuring residual stresses is the hole-drilling strain gage method described in ASTM Standard E837. With this method, a specially configured electrical resistance strain gage rosette is bonded to the test object's surface, and a small shallow hole is drilled through the center of the rosette. The local changes in strain due to the introduction of the hole are measured, and the relaxed residual stresses are computed from these measurements. The practicality and accuracy of this method are directly related to the precision with which the hole is drilled through the center of the strain gage rosette. The Micro-Measurements RS-200 milling guide provides a practical means to accomplish this task.

Watch a short RS-200 Video here.

Equipment to Support Residual Stress Testing

- Special Residual Stress Rosettes in a variety of sizes

- Gage Application Kits that contain the adhesive and installation supplies that are necessary for a successful strain gage installation

- H-Drill Software for data reduction that is written by an industry-leading expert in the field of residual stress analysis

- The Model P3 Strain Indicator and Recorder are used to capture the signal from the rosettes.

You will find that Micro-Measurements offers a complete solution for the measurement of residual stress testing using the hole-drilling technique and see the details below. Please contact our Applications Engineering Department if you would like to find out more about residual stress testing or other products offered by Micro-Measurements.

RS-200 Milling Guide Equipment

|

PART NUMBER |

DESCRIPTION |

|

|

|

|

MMP920-000265 |

RS-200 MILLING GUIDE- COMPLETE UNIT |

|

MMF336166 |

RS-200-CK2 GRIP ADHESIVE (5 PACK) |

|

REPLACEMENT PARTS |

|

|

|

|

|

MMF336166 |

RS-200-CK2 GRIP ADHESIVE |

|

MMP920-000193 |

RS-200-FP REPLACEMENT FOOT PADS QTY 3 WITH TEMPLATE |

|

MMP100-010569 |

RS-200 END MILL .062 |

|

MMP100-010573 |

RS-200 END MILL .125 |

|

MMP20X100033 |

RS-200-B1 REPLACEMENT BULB FOR LIGHTSOURCE |

|

MMP27X300006 |

ATC-200-062 CARBIDE-TIPPED CUTTERS (5/PKG) |

|

MMP27X300007 |

ATC-200-031 CARBIDE-TIPPED CUTTERS (5/PKG) |

Residual Stress Strain Gage Rosettes

|

GAGE PATTERN AND DESIGNATION |

RESISTANCE IN OHMS |

DIMENSIONS |

|||||||||||||

|

GAGE LENGTH |

GRID CTR’LINE DIA. |

TYPICAL HOLE DIA. |

MATRIX |

||||||||||||

|

Min. |

Max. |

Length |

Width |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

CEA-XX-062UL-120 |

|

120 ± 0.4% |

0.062 |

0.202 |

0.06 |

0.08 |

0.50 |

0.62 |

|||||||

|

1.57 |

5.13 |

1.5 |

2.0 |

12.7 |

15.7 |

||||||||||

|

Fully encapsulated with large copper-coated soldering tabs. Same pattern geometry as 062RE pattern. |

|||||||||||||||

|

CEA-XX-062UM-120 |

|

120 ± 0.4% |

0.062 |

0.202 |

0.06 |

0.08 |

0.38 |

0.48 |

|||||||

|

1.57 |

5.13 |

1.5 |

2.0 |

9.6 |

12.2 |

||||||||||

|

Fully encapsulated with large copper-coated soldering tabs and special trim alignment marks. Trim line spaced 0.068 in (1.73 mm) from hole center. Limitations may exist in data reduction equations. |

|||||||||||||||

|

EA-XX-062RE-120 EA-XX-062RE-120/SE |

|

120 ± 0.2% 120 ± 0.4% |

0.062 |

0.202 |

0.06 |

0.08 |

0.42 |

0.42 |

|||||||

|

1.57 |

5.13 |

1.5 |

2.0 |

10.7 |

10.7 |

||||||||||

|

Most widely used RE pattern for general-purpose residual stress measurement applications. |

|||||||||||||||

|

EA-XX-031RE-120 EA-XX-031RE-120/SE |

|

120 ± 0.2% 120 ± 0.4% |

0.031 |

0.101 |

0.03 |

0.04 |

0.29 |

0.29 |

|||||||

|

0.79 |

2.56 |

0.8 |

1.0 |

7.4 |

7.4 |

||||||||||

|

Due to small pattern size, measurement error can be magnified by slight mislocation of drill hole. Pattern not recommended for general-purpose applications. |

|||||||||||||||

|

EA-XX-125RE-120 EA-XX-125RE-120/SE |

|

120 ± 0.2% 120 ± 0.4% |

0.125 |

0.404 |

0.12 |

0.16 |

0.78 |

0.78 |

|||||||

|

3.18 |

10.26 |

3.0 |

4.1 |

19.8 |

19.8 |

||||||||||

|

Larger version of the 062RE pattern. |

|||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||

Related Products

|

GAK-2-200 Gage Installation Kit |

P3 Strain Indicator and Recorder |

H DRILL SOFTWARE |

Reference Documentation and Video:

B-127 Instruction Bulletin for Strain Gage Installations with M-Bond 200

TRAINING

Benefit from an extensive series of regularly scheduled, hands-on technical workshops and short courses.

HOW TO VIDEOS

We offer a wide variety of "How-To-Videos" hosted by expert application engineers. Step-By-Step training can be found here.

KNOWLEDGE BASE

Unlock a wealth of knowledge, from calculators to technical documents, to help you manage our strain gage and PhotoStress® products.

RESOURCES

Learn about our stress analysis products, watch informative videos, and explore our large knowledge base.